From a physics perspective, brakes on automobiles are built to convert kinetic energy (your moving vehicle) into heat energy (friction). In a car, for example, the car then stops because of the energy conversion.

Read Full Article →

Drilling rigs provide an invaluable service for companies that need to dig deep, with the convergence of drilling rig components and parts working together to do their job.

However, the reality of this situation is that the rigorous work being performed will likely hasten the onset of drilling rig repairs at some point.

Read Full Article →

A hydraulic pump uses hydraulic power pump drives (PPDs) engineered for agricultural markets, as well as construction, forestry, petroleum, and marine industries. The hydraulic pump is a mechanical device that produces hydraulic energy from mechanical power. It generates flow with sufficient power, which will allow it to overcome pressure from the load.

Read Full Article →

Gearboxes are an essential part of so many pieces of machinery. If you want to keep your gearbox functioning at its optimal performance, then regular maintenance should be done. The best way to maintain your gearbox is to check it regularly to determine potential failures and fix them before they happen. This will keep you from those surprise breakdowns at the most inconvenient times.

To keep your gearbox functioning at it best and for a longer time, here are some key maintenance tips to consider.

Read Full Article →

Originator and the world’s leading manufacturer of coil spring automatic taglines and magnet reels.

Originator and the world’s leading manufacturer of coil spring automatic taglines and magnet reels.

The Rud-O-Matic Tagline holds a clamshell bucket steady regardless of the boom angle while the bucket and its load is suspended in the air. Operation is completely automatic after installation. Bell Guide fairlead requires no sheaves, pins or lubrication.

Read Full Article →

If you are working on one of the following types of boats:

Work, Crew, Ferry, Dredge, Fishing or Tugs

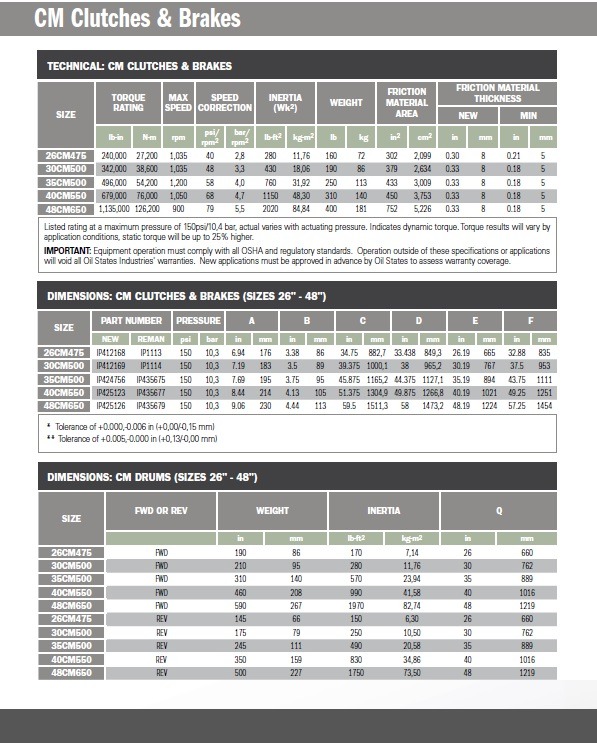

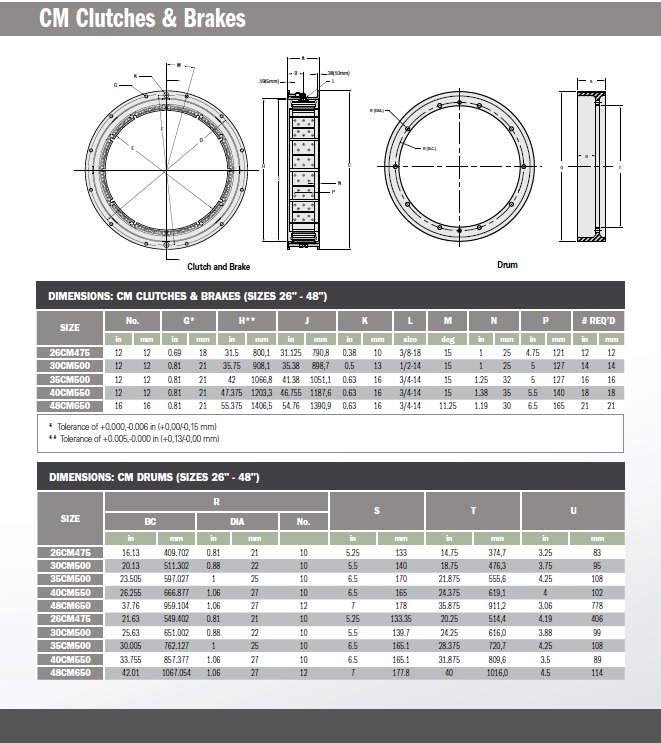

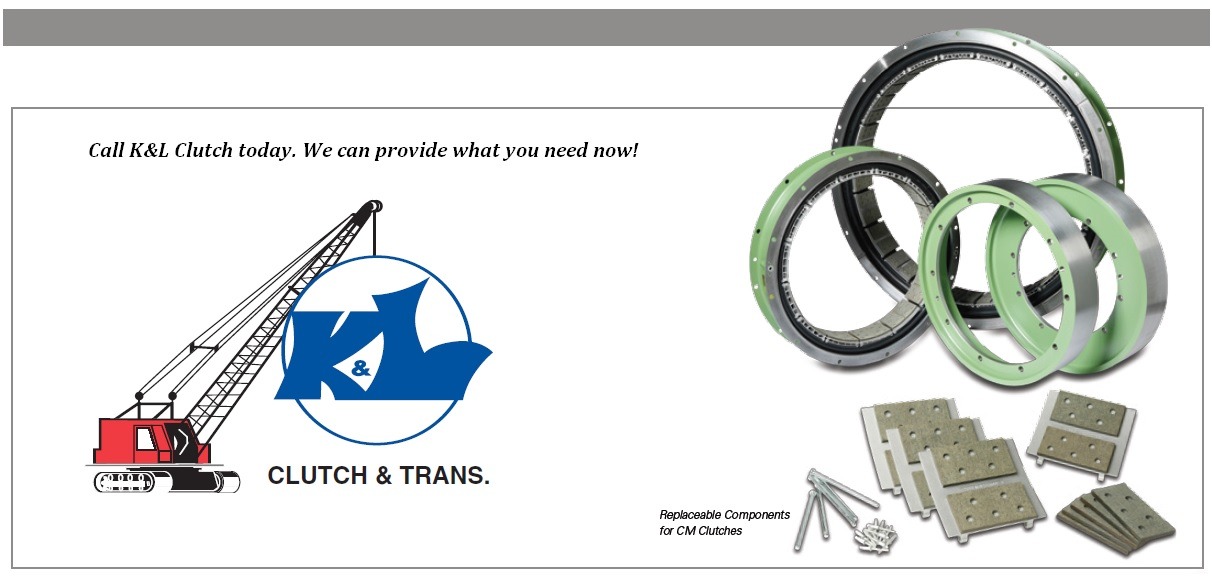

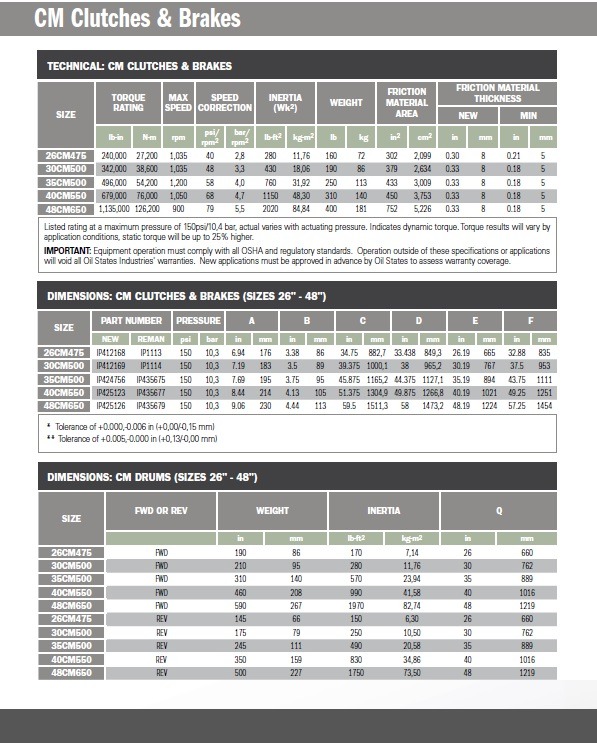

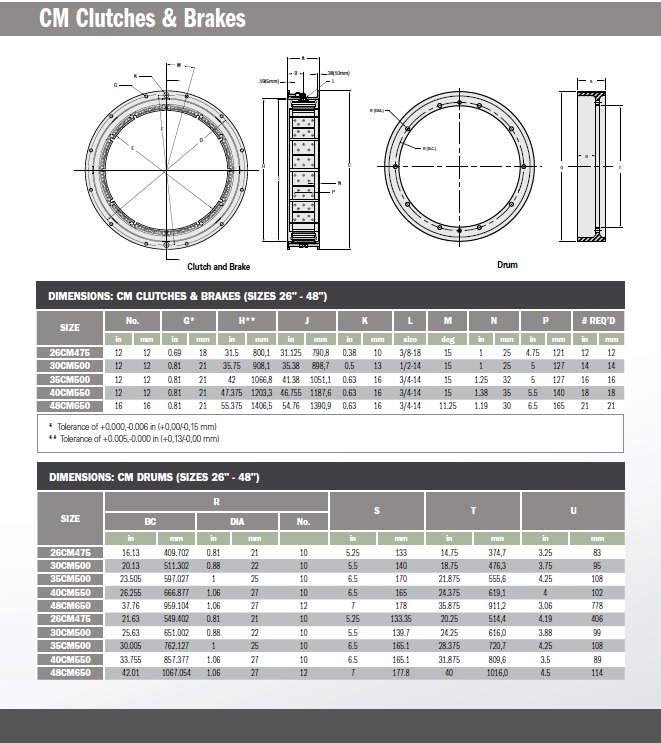

Chances are you will be in need of an Oil States CM or VC style marine clutch or drum that K&L now offers. Oil States CM clutch technology is the preferred choice for the marine industry and K&L now offers all five sizes 26″, 30″, 35″, 40″ and 48″.

The CM is a ventilated version of the CB clutch, providing greater heat dissipation through the ventilated friction shoe assembly. The CM design permits slippage during vessel maneuvering and cycling engagement.

DON’T THROW THOSE OLD RIMS AWAY!! Ask about the reman program for all sizes that can save you up to 35%, which carry the same warranty as new.

Please contact K&L Clutch and Transmission for all of your marine equipment and product needs.

Contact Us

There are many advantages to using heavy machinery. In the modern world, we are coming to depend more and more on things like heavy duty transmissions and other industrial machinery. Let’s look at some of the top reasons why so many people appreciate this type of technology.

There are many advantages to using heavy machinery. In the modern world, we are coming to depend more and more on things like heavy duty transmissions and other industrial machinery. Let’s look at some of the top reasons why so many people appreciate this type of technology.

1. Greater Productivity

There is no question that industrial machinery makes many tasks faster and more efficient. The same job that might take days or several people to accomplish can be done in hours or even minutes using the right equipment. Whether they are being used for business or leisure activities, this type of machinery allows you to be far more productive in many ways.

2. Cost Effectiveness

Because they allow you to accomplish so much more in less time, these devices save you money. There is the initial cost of purchasing them and then they must be properly maintained, however, with the right care, they save money in terms of time and labor costs. This helps businesses earn higher profits.

3. LESS PHYSICAL LABOR

Operating heavy machinery is far less taxing on the human body than using other types of tools. Aside from the economic benefits, people with access to this type of machinery don’t have to work as hard physically. This translates into shorter workdays and more leisure time.

4. The ability to accomplish the amazing

One of the reasons we all love heavy duty machines is that they embody the potential to accomplish amazing feats of construction, excavation and demolition that have never before been possible. Manpower has been used to accomplish great feats, including the construction of the Pyramids and the Great Wall of China, but modern technology allows massive undertakings in rapid time.

5. They’re just so cool!

Many people appreciate this type of machinery simply for its power and aesthetic qualities, in addition to the many practical benefits it can add to your life. This is why many people enjoy trade shows that feature such equipment or browsing through magazines, product catalogs or websites that feature it.

The above are some of the top reasons why heavy machinery is so widely admired. It can be advantageous to everyone, from workers to business owners. If you are looking for repair work, or new clutch or transmission parts for your heavy machinery, look no further!

Contact Us

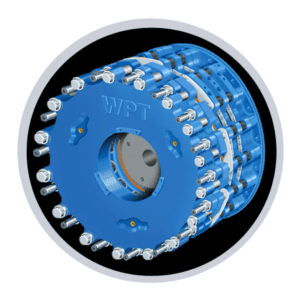

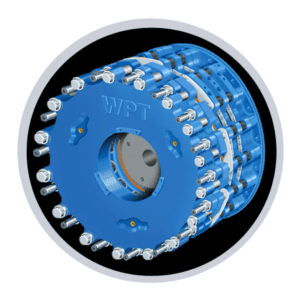

To complement our WPT Mechanical line of power products, K & L Clutch is pleased to announce their appointment as the “Full Line Distributor” in North Texas for WPT Power Products. Effective 2/1/13 we will handle the complete line of outstanding products that WPT offers. This includes Type 1 and Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment, K & L Clutch becomes the only certified service center for WPT Power Products in the North Central Texas area. If your unit is in need of repair, we can do it.

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment, K & L Clutch becomes the only certified service center for WPT Power Products in the North Central Texas area. If your unit is in need of repair, we can do it.

We are ready to service you now. Please call any of our experienced sales associates and ask more about the “Full Line” of WPT products we can serve you with.

Contact us for more information. We’ll get your project back up and running in no time.

Order Now

Back in August of 2009 we released a post digging into the science of cranes, their components and how everything works together. We decided it was time for an update, but you can still see the former boom crane post here: https://obtainable-rake.flywheelsites.com/cranes/science-behind-boom-cranes/

The Parts of A Crane

A quick look at crane terminology.

The Boom: The boom of a crane is the long, telescopic, or fixed, arm that is used to move objects.

The Boom: The boom of a crane is the long, telescopic, or fixed, arm that is used to move objects.- The Counterweights: The counterweights are stabilizers placed near the cab’s exterior that prevent the crane from becoming unbalanced when lifting heavy loads.

- The Jib: The jib is the lattice-like structure that gives the boom the freedom to extend.

- The Rotex Gear: The Rotex gear affords the crane the ability to rotate its apparatus, thereby better enabling it to do its job from awkward standpoints. Hook rollers are also used in some crane applications.

Read Full Article →

Here at K&L Clutch & Transmission, we pride ourselves deeply on the unmatched level of clutch and transmission service and maintenance we provide. Our industry-leading technicians and engineers are constantly pioneering new, better ways to improve part repair and replacement turnaround time in order to better help our customers keep their projects up and running.

Read Full Article →

Originator and the world’s leading manufacturer of coil spring automatic taglines and magnet reels.

Originator and the world’s leading manufacturer of coil spring automatic taglines and magnet reels.

There are many advantages to using heavy machinery. In the modern world, we are coming to depend more and more on things like

There are many advantages to using heavy machinery. In the modern world, we are coming to depend more and more on things like  Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment,

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment,  The Boom: The boom of a crane is the long, telescopic, or fixed, arm that is used to move objects.

The Boom: The boom of a crane is the long, telescopic, or fixed, arm that is used to move objects.