A hydraulic pump uses hydraulic power pump drives (PPDs) engineered for agricultural markets, as well as construction, forestry, petroleum, and marine industries. The hydraulic pump is a mechanical device that produces hydraulic energy from mechanical power. It generates flow with sufficient power, which will allow it to overcome pressure from the load.

It is important to have correctly sized hydraulic power pump drives for the power unit. The process is quite straightforward, but it can vary according to the power source type used. For instance, an electric motor typically has lesser operating torque than its initial torque. On the other hand, engines powered by gasoline and diesel often have a more balanced torque to speed ratio, which delivers a steady among of torque at both low and high running speed rates.

Nevertheless, as a rule of thumb, the hydraulic power pump drive used for diesel or gasoline motors should be at least double the power rating of the electric motor fit for the same system.

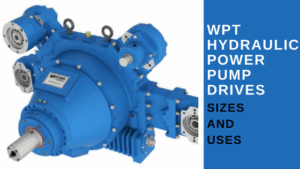

Power Pump Drives Sizes

WPT Power Corporation has introduced a new line of PPDs that come in four sizes:

PPDM

This particular unit has a weight of 430 lbs. and measures 10.1 inches long. The maximum torque capacity of the unit is 1,475 lb-ft and its operating speed is at a maximum of 2,600 RPM. PPDM is one of the WPT power parts designed for use in SAE 1 housings that come with 14-inch flywheels. For those that use SAE2 or 3, this unit fits those with 11.5-inch flywheels.

PPDM has a total of four pump mounting surfaces, ranging from SAE D to B-B. It can generate up to 235 horsepower for pumping whenever in use.

PPDL

PPDL is much heavier than PPDM as it weighs 770 lbs. It is also longer with 12.2 inches in length. It is for mounting to SAE 1 housings with the same measurement of flywheels as with PPDM, although it cannot mount on other housings.

Its maximum torque capacity is greater as it can reach up to 2,470 lb-ft, but the maximum operating speed is slower than PPDM because it only reaches 2,200 RPM. PPDL can be used with up to eight pump mounting surfaces, ranging from SAE D to B-B as well and can deliver much greater horsepower of up to 400 HP.

PPDS

This unit is smaller and lighter than both PPDL and PPDM. PPDS weighs just 110 lbs. and measures 8.6 inches in length. PPDS is for use in mounting on SAE 4 housings that come with 10-inch flywheels. The maximum torque capacity is almost similar to that of PPDM with 413 lb-ft. However, the operating speed can reach a maximum of 3,000 RPM, faster than the other two sizes. It is mountable to SAE 4 housings, which have 10-inch flywheels. WPT power parts for hydraulic pump drives of this size have two SAE B framing faces and can deliver up to 58 HP.

PPDX

Finally, the last size, which is the biggest one, weighs 1,170 lbs. and measures 14.3 inches long. Made for SAE 0 housings with flywheels that are around 18 inches, PPDX is also mountable to SAE 1 that has 14-inch flywheels.

Full torque capacity of the unit is 4,650 lb-ft and it can operate at speeds up to 2,100 RPM. PPDX power pump drives come with eight pump mounting faces, ranging from SAE D to B-B. They can also deliver pumping powers of up to 535 HP.

Installation of hydraulic power pump drives is between the engine and the power take-off. They are versatile and sturdy, allowing them to handle several clutched or live pumps. PPDs are self-contained, which is why they are often usable even without lubrication.