From a physics perspective, brakes on automobiles are built to convert kinetic energy (your moving vehicle) into heat energy (friction). In a car, for example, the car then stops because of the energy conversion.

Read Full Article →

Heavy equipment requires high-performance braking systems that withstand extreme thermal loads. But, more importantly, they should keep the brakes running cool. Three types of braking systems can be used depending on the specific industrial machine.

Read Full Article →

An industrial air clutch is a plate connected to a drive shaft of power machinery, and when engaged, it uses compressed air to slow down or stop the engine by disengaging it from what is driven. The industrial air clutch uses air instead of hydraulics or centrifugal forces to stop heavy machines.

Read Full Article →

Traditional disk brakes usually experience very high temperatures which can have severely detrimental effects on their performance. To lower these temperatures, the use of fluids such as water is imperative to eliminate much of this friction-generated heat.

Read Full Article →

2015 was a great year for us.

We achieved some outstanding accomplishments; namely, winning a handful of awards:

- The Distributor with the Largest Increase in Sales!

- Top 5 in Mechanical PTO Sales

- Top 5 in Overall Sales

- Top 5 in Assembly Sales

If anyone is looking for WPT Power products, you now know who to call for the best!

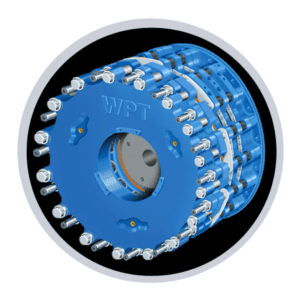

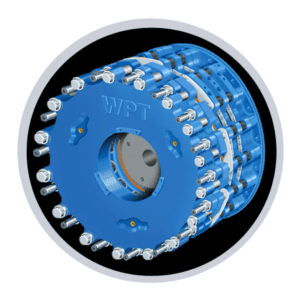

To complement our WPT Mechanical line of power products, K & L Clutch is pleased to announce their appointment as the “Full Line Distributor” in North Texas for WPT Power Products. Effective 2/1/13 we will handle the complete line of outstanding products that WPT offers. This includes Type 1 and Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment, K & L Clutch becomes the only certified service center for WPT Power Products in the North Central Texas area. If your unit is in need of repair, we can do it.

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment, K & L Clutch becomes the only certified service center for WPT Power Products in the North Central Texas area. If your unit is in need of repair, we can do it.

We are ready to service you now. Please call any of our experienced sales associates and ask more about the “Full Line” of WPT products we can serve you with.

Contact us for more information. We’ll get your project back up and running in no time.

Order Now

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment,

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment,