An industrial air clutch is a plate connected to a drive shaft of power machinery, and when engaged, it uses compressed air to slow down or stop the engine by disengaging it from what is driven. The industrial air clutch uses air instead of hydraulics or centrifugal forces to stop heavy machines.

Read Full Article →

Grab. Spin. Decouple. Repeat.

Grab. Spin. Decouple. Repeat.

At one level, clutches really are that simple. But pneumatic clutches are just one example of what a few innovative twists can do to complicate (and improve) the process.

So let’s start with the basics:

Read Full Article →

Drilling rigs provide an invaluable service for companies that need to dig deep, with the convergence of drilling rig components and parts working together to do their job.

However, the reality of this situation is that the rigorous work being performed will likely hasten the onset of drilling rig repairs at some point.

Read Full Article →

2015 was a great year for us.

We achieved some outstanding accomplishments; namely, winning a handful of awards:

- The Distributor with the Largest Increase in Sales!

- Top 5 in Mechanical PTO Sales

- Top 5 in Overall Sales

- Top 5 in Assembly Sales

If anyone is looking for WPT Power products, you now know who to call for the best!

If you are working on one of the following types of boats:

Work, Crew, Ferry, Dredge, Fishing or Tugs

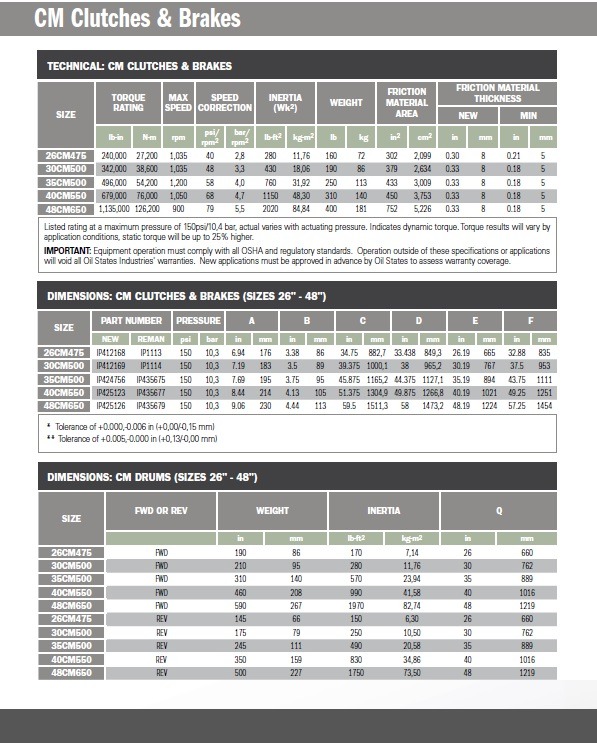

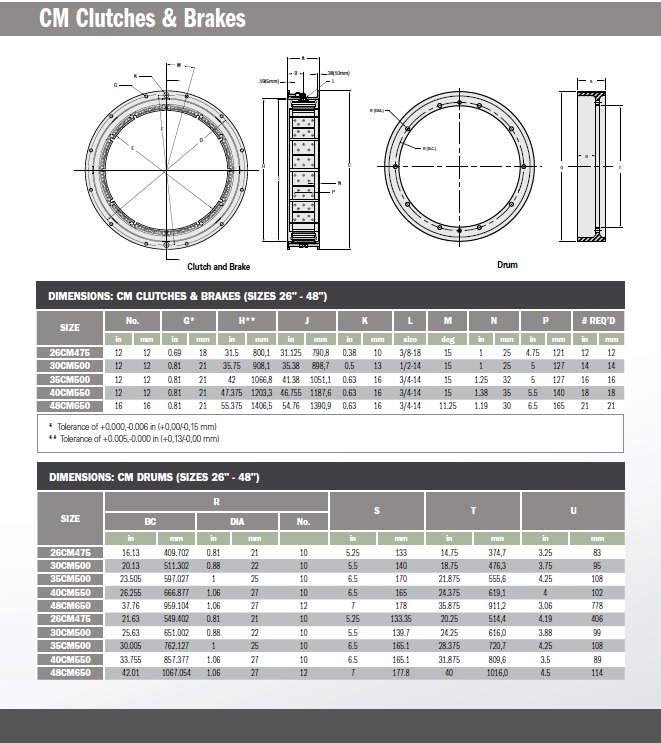

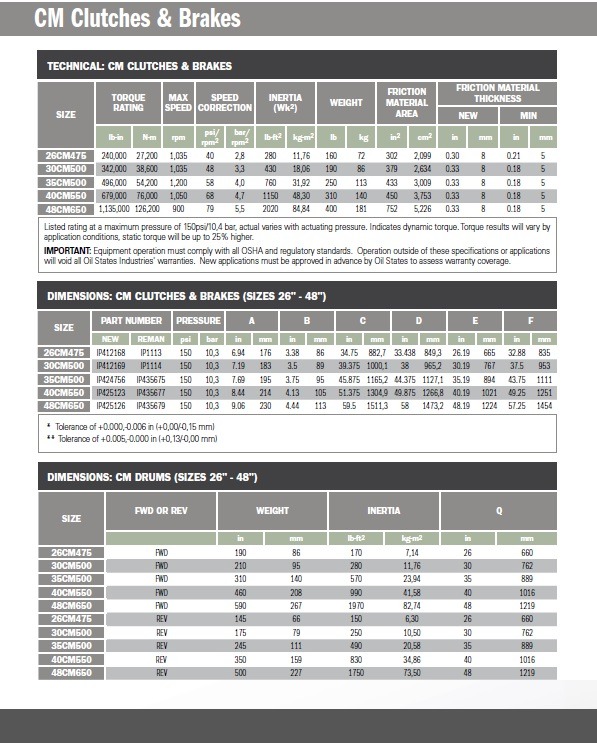

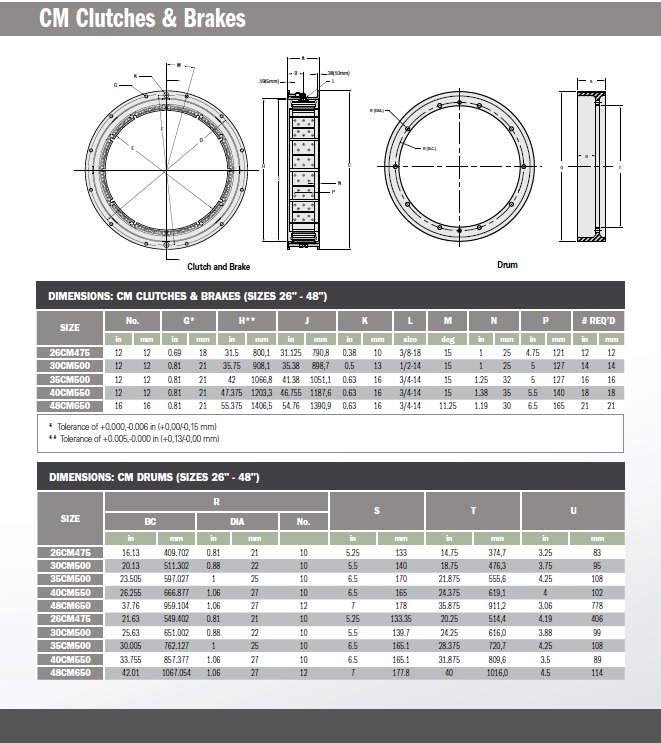

Chances are you will be in need of an Oil States CM or VC style marine clutch or drum that K&L now offers. Oil States CM clutch technology is the preferred choice for the marine industry and K&L now offers all five sizes 26″, 30″, 35″, 40″ and 48″.

The CM is a ventilated version of the CB clutch, providing greater heat dissipation through the ventilated friction shoe assembly. The CM design permits slippage during vessel maneuvering and cycling engagement.

DON’T THROW THOSE OLD RIMS AWAY!! Ask about the reman program for all sizes that can save you up to 35%, which carry the same warranty as new.

Please contact K&L Clutch and Transmission for all of your marine equipment and product needs.

Contact Us

Ever wondered how air clutches work? K&L Clutch and Transmission has the expert answer!

Ever wondered how air clutches work? K&L Clutch and Transmission has the expert answer!

An industrial air clutch for heavy machinery performs a very important job in relation to an engine and how power or torque is transferred. A typical engine has an output shaft as can be seen on an automobile engine at the flywheel position. A clutch is a device, usually a system of plates or grabbing disks that engage the power from the flywheel and transfer it to the transmission. A PTO, or power takeoff shaft, performs the same function and is commonly found on heavy construction equipment or farm machinery. The engine clutch engages with the PTO shaft so that it may spin or drive another component, like a tiller or peripheral device. Compressed air is used to engage or disengage the engine from the driven component, rather than using hydraulic (oil) or centrifugal force.

Read Full Article →

Grab. Spin. Decouple. Repeat.

Grab. Spin. Decouple. Repeat.

Ever wondered how air clutches work? K&L Clutch and Transmission has the expert answer!

Ever wondered how air clutches work? K&L Clutch and Transmission has the expert answer!