Have you ever asked yourself how marine crafts survive long cruises across oceans and seas? The marine environment is hazardous. All processes to go through smoothly, ensure that safety goes first by having quality clutches from one of the best manufacturing companies installed in your marine vessels and anchor spots.

Read Full Article →

Grab. Spin. Decouple. Repeat.

Grab. Spin. Decouple. Repeat.

At one level, clutches really are that simple. But pneumatic clutches are just one example of what a few innovative twists can do to complicate (and improve) the process.

So let’s start with the basics:

Read Full Article →

Drilling rigs provide an invaluable service for companies that need to dig deep, with the convergence of drilling rig components and parts working together to do their job.

However, the reality of this situation is that the rigorous work being performed will likely hasten the onset of drilling rig repairs at some point.

Read Full Article →

2015 was a great year for us.

We achieved some outstanding accomplishments; namely, winning a handful of awards:

- The Distributor with the Largest Increase in Sales!

- Top 5 in Mechanical PTO Sales

- Top 5 in Overall Sales

- Top 5 in Assembly Sales

If anyone is looking for WPT Power products, you now know who to call for the best!

Industrial Clutch is a clutch manufacturer under the Altra Industrial Motion Group. The mechanical Industrial clutches we support are used in Allison Torque Converters. These over-center clutches are used to disconnect the converter from the engine.

Read Full Article →

If you are working on one of the following types of boats:

Work, Crew, Ferry, Dredge, Fishing or Tugs

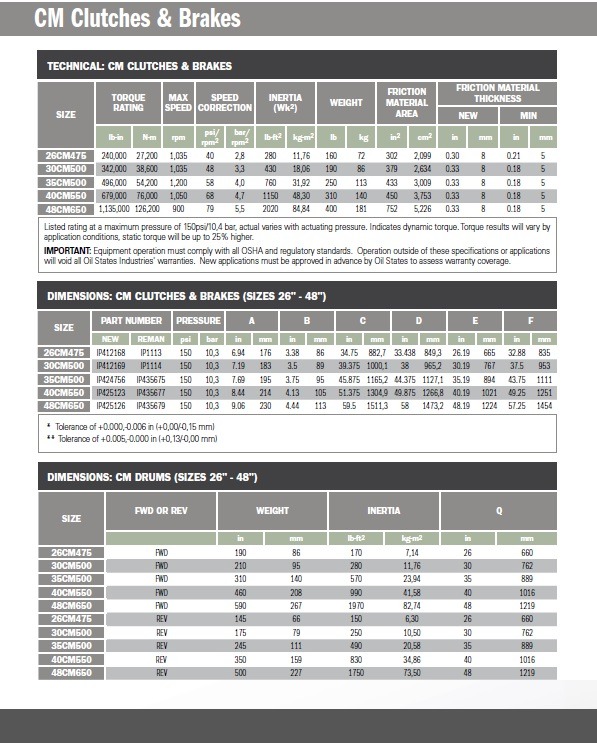

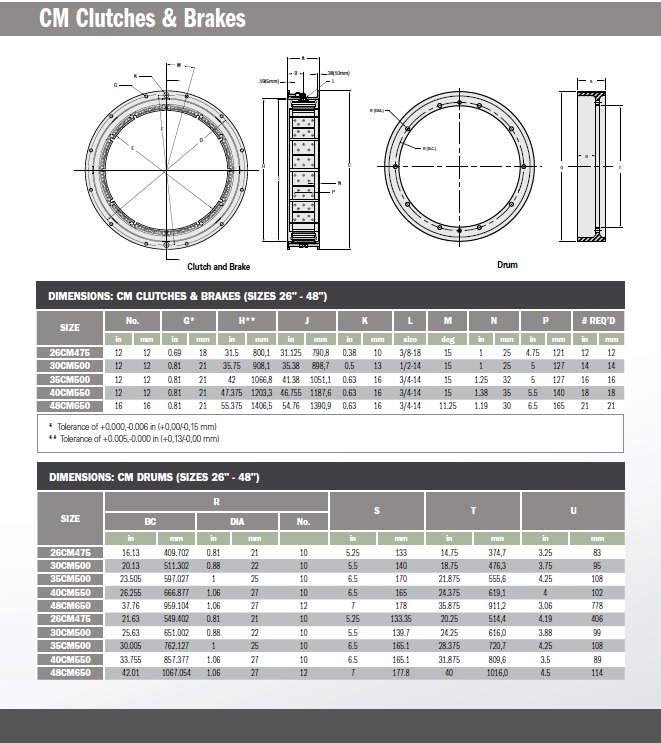

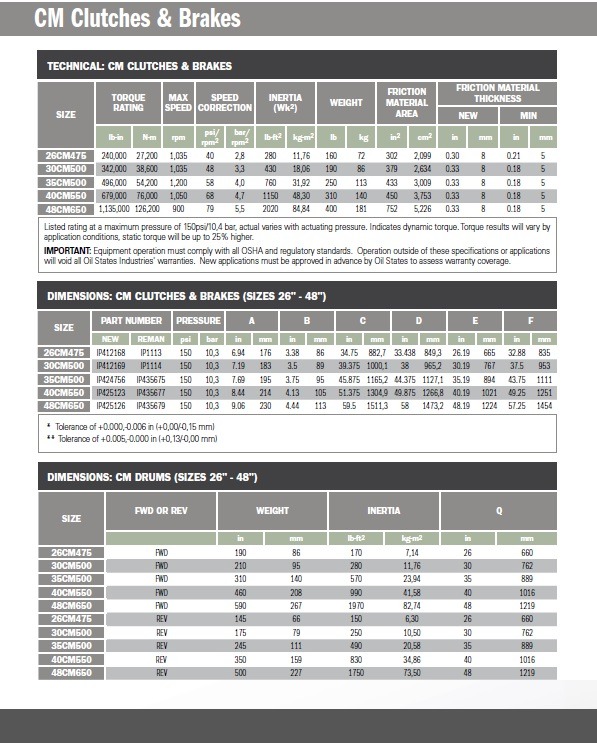

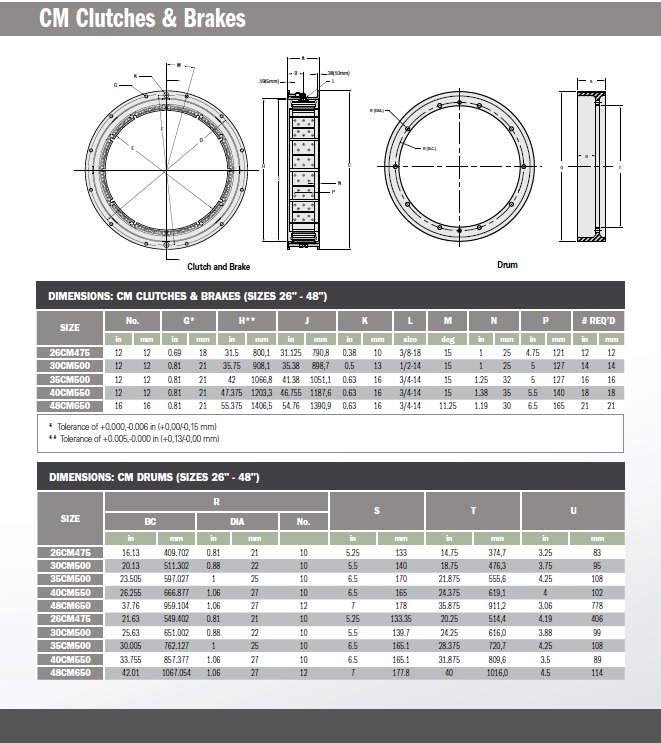

Chances are you will be in need of an Oil States CM or VC style marine clutch or drum that K&L now offers. Oil States CM clutch technology is the preferred choice for the marine industry and K&L now offers all five sizes 26″, 30″, 35″, 40″ and 48″.

The CM is a ventilated version of the CB clutch, providing greater heat dissipation through the ventilated friction shoe assembly. The CM design permits slippage during vessel maneuvering and cycling engagement.

DON’T THROW THOSE OLD RIMS AWAY!! Ask about the reman program for all sizes that can save you up to 35%, which carry the same warranty as new.

Please contact K&L Clutch and Transmission for all of your marine equipment and product needs.

Contact Us

There are a huge number of different transmissions being put to use in a wide variety of simple and complex machinery. Each model uses different types of transmission designs to convert power and drive the engine. With each variety of system comes different abilities and, of course, their own set of unique problems. The most uncommon transmissions are those being put to use in heavy machinery such as hydrostatic transmissions, hydrodynamic systems, and electric transmissions. In each of these cases, the transmission system is essentially converting power from its source for transmission into various gears and components. This transmission mechanism differs accordingly. In virtually all cases, however, the clutch and transmission of a vehicle will be intricately related, controlling the transition between gears which are responsible for transferring power. The number of gears and precise machining necessary for a clutch and transmission to work together properly ends up becoming the source of a great many problems in the engine as a whole. Read Full Article →

There are a huge number of different transmissions being put to use in a wide variety of simple and complex machinery. Each model uses different types of transmission designs to convert power and drive the engine. With each variety of system comes different abilities and, of course, their own set of unique problems. The most uncommon transmissions are those being put to use in heavy machinery such as hydrostatic transmissions, hydrodynamic systems, and electric transmissions. In each of these cases, the transmission system is essentially converting power from its source for transmission into various gears and components. This transmission mechanism differs accordingly. In virtually all cases, however, the clutch and transmission of a vehicle will be intricately related, controlling the transition between gears which are responsible for transferring power. The number of gears and precise machining necessary for a clutch and transmission to work together properly ends up becoming the source of a great many problems in the engine as a whole. Read Full Article →

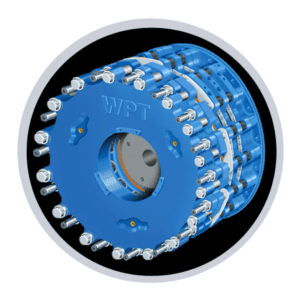

To complement our WPT Mechanical line of power products, K & L Clutch is pleased to announce their appointment as the “Full Line Distributor” in North Texas for WPT Power Products. Effective 2/1/13 we will handle the complete line of outstanding products that WPT offers. This includes Type 1 and Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment, K & L Clutch becomes the only certified service center for WPT Power Products in the North Central Texas area. If your unit is in need of repair, we can do it.

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment, K & L Clutch becomes the only certified service center for WPT Power Products in the North Central Texas area. If your unit is in need of repair, we can do it.

We are ready to service you now. Please call any of our experienced sales associates and ask more about the “Full Line” of WPT products we can serve you with.

Contact us for more information. We’ll get your project back up and running in no time.

Order Now

Pneumatic clutches are very powerful and an excellent fit for the large industrial machines your company depends on for your toughest job-site challenges, including auto cranes and other construction vehicles.

Pneumatic clutches are very powerful and an excellent fit for the large industrial machines your company depends on for your toughest job-site challenges, including auto cranes and other construction vehicles.

Read Full Article →

24-Hour Field Service & Troubleshooting

Time spent not working is money poured down the drain, so the ability to respond instantly as soon as a breakdown happens is critical. Nonstop service capabilities can make the difference between project profitability and failure “” especially since so many industries we work with are hard at work around the clock. From our service center and machine shop in North Texas, we can respond at any time a need arises, providing excellent industrial equipment services.

Factor in time zone changes, and this flexibility becomes even more vital””when work breaks down in the middle of the day in the Middle East, you shouldn’t have to wait until the normal business day starts up again in Dallas to get technical support and troubleshooting advice. Read Full Article →

Grab. Spin. Decouple. Repeat.

Grab. Spin. Decouple. Repeat.

There are a huge number of different transmissions being put to use in a wide variety of simple and complex machinery. Each model uses different types of transmission designs to convert power and drive the engine. With each variety of system comes different abilities and, of course, their own set of unique problems. The most uncommon transmissions are those being put to use in heavy machinery such as hydrostatic transmissions, hydrodynamic systems, and electric transmissions. In each of these cases, the transmission system is essentially converting power from its source for transmission into various gears and components. This transmission mechanism differs accordingly. In virtually all cases, however, the clutch and transmission of a vehicle will be intricately related, controlling the transition between gears which are responsible for transferring power. The number of gears and precise machining necessary for a

There are a huge number of different transmissions being put to use in a wide variety of simple and complex machinery. Each model uses different types of transmission designs to convert power and drive the engine. With each variety of system comes different abilities and, of course, their own set of unique problems. The most uncommon transmissions are those being put to use in heavy machinery such as hydrostatic transmissions, hydrodynamic systems, and electric transmissions. In each of these cases, the transmission system is essentially converting power from its source for transmission into various gears and components. This transmission mechanism differs accordingly. In virtually all cases, however, the clutch and transmission of a vehicle will be intricately related, controlling the transition between gears which are responsible for transferring power. The number of gears and precise machining necessary for a  Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment,

Type 2 Pneumatic and Hydraulic PTOs, Power Grip and PO Clutches, Water Cooled Brakes, Low Inertia Clutches and Brakes, Pump drives, and Caliper Brakes. With this appointment,  Pneumatic clutches

Pneumatic clutches